The production department of YTS consists of the following four sections.

The injection molding section, Machining section, PTFE diaphragm manufacturing section and assembly section.

Injection molding section

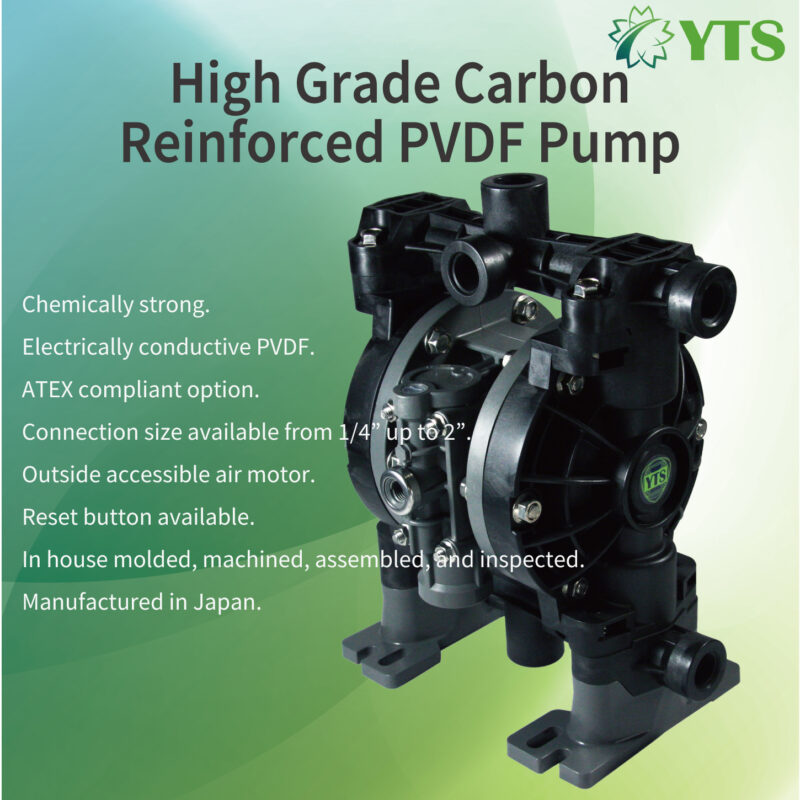

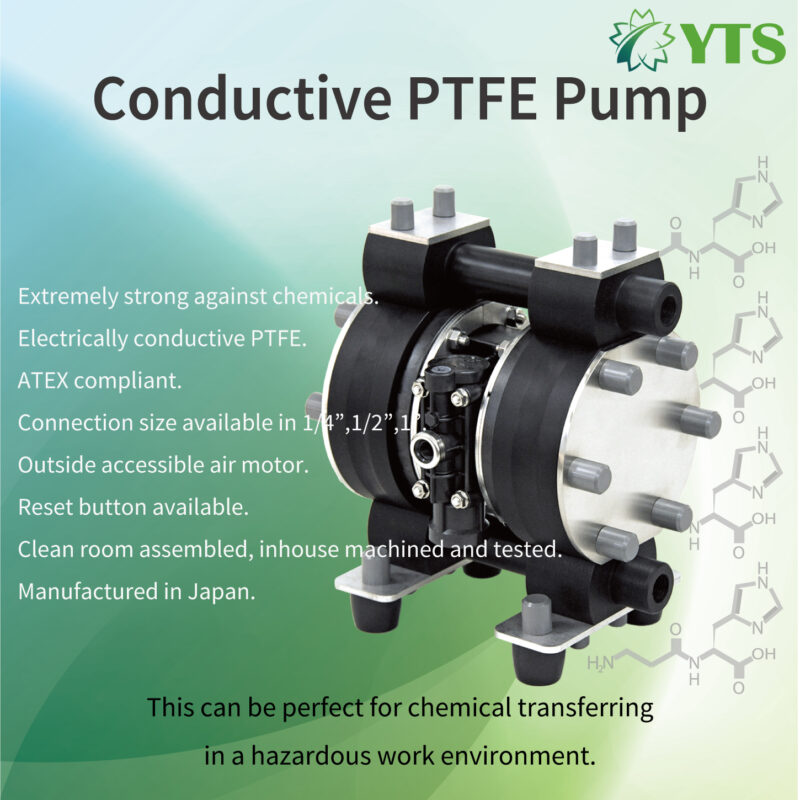

The art plastic injection molding facility with 13 screw type high pressure plastic injection molding machines ranging from 15 to 1,300 tons. YTS can produce many different precision pump parts manufactured from Japanese source raw material including super engineering type plastics. YTS is able to produce high quality, precise and dimensionally stable pumps for all kinds of chemical transfer applications.

The art plastic injection molding facility with 13 screw type high pressure plastic injection molding machines ranging from 15 to 1,300 tons. YTS can produce many different precision pump parts manufactured from Japanese source raw material including super engineering type plastics. YTS is able to produce high quality, precise and dimensionally stable pumps for all kinds of chemical transfer applications.

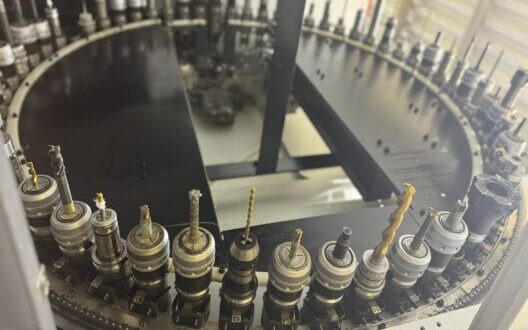

Machining section

After the completion of the Plastic Injection process, all machining work done on the pump liquid wetted mating surfaces, holes and screw threads etc. is carried out internally by our highly skilled staff. YTS owns many large Machining Centers, CNC lathes and General-purpose lathes. YTS also prepares and carries out the machining work on many of pump metallic components such as aluminium and stainless chambers, manifolds, center rods and center disks etc.

After the completion of the Plastic Injection process, all machining work done on the pump liquid wetted mating surfaces, holes and screw threads etc. is carried out internally by our highly skilled staff. YTS owns many large Machining Centers, CNC lathes and General-purpose lathes. YTS also prepares and carries out the machining work on many of pump metallic components such as aluminium and stainless chambers, manifolds, center rods and center disks etc.

PTFE diaphragm manufacturing

YTS manufactures PTFE diaphragms in house for all sizes and does not outsource in order to ensure the best quality. Before molding, the PTFE sheets are carefully controlled and prepared by YTS’s own manufacturing method for better PTFE strength. The molded PTFE diaphragms are furnaced under strictly regulated temperatures for a specified time. Even after manufacturing, we check the diaphragms thoroughly with the help of magnifiers so that we do not miss any dirt and dents which might not be visible to the naked eye. Because we boast about our PTFE diaphragms, the single PTFE diaphragm option is in our standard lineup.

YTS manufactures PTFE diaphragms in house for all sizes and does not outsource in order to ensure the best quality. Before molding, the PTFE sheets are carefully controlled and prepared by YTS’s own manufacturing method for better PTFE strength. The molded PTFE diaphragms are furnaced under strictly regulated temperatures for a specified time. Even after manufacturing, we check the diaphragms thoroughly with the help of magnifiers so that we do not miss any dirt and dents which might not be visible to the naked eye. Because we boast about our PTFE diaphragms, the single PTFE diaphragm option is in our standard lineup.

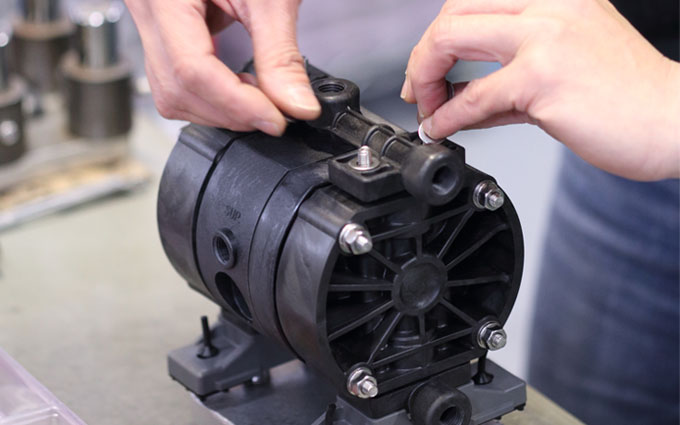

Assembly section

YTS’s large range of pumps are all manufactured and assembled at our Sakura facility. Every pump goes through inspection and a series of test including vacuum pressure test, leak test and pump operation test after assembly. The majority of all pump parts are kept in stock and pumps are manufactured following a strict Just-in-time manufacturing process ensuring very short lead-time from order dispatch.

YTS’s large range of pumps are all manufactured and assembled at our Sakura facility. Every pump goes through inspection and a series of test including vacuum pressure test, leak test and pump operation test after assembly. The majority of all pump parts are kept in stock and pumps are manufactured following a strict Just-in-time manufacturing process ensuring very short lead-time from order dispatch.